A systematic transition to a circular economy can equip businesses to realize substantial gains in productivity and profits. With the influence of big data and smart technologies, discover how Annata 365 enables technological approaches that guide and accelerate circular solutions.

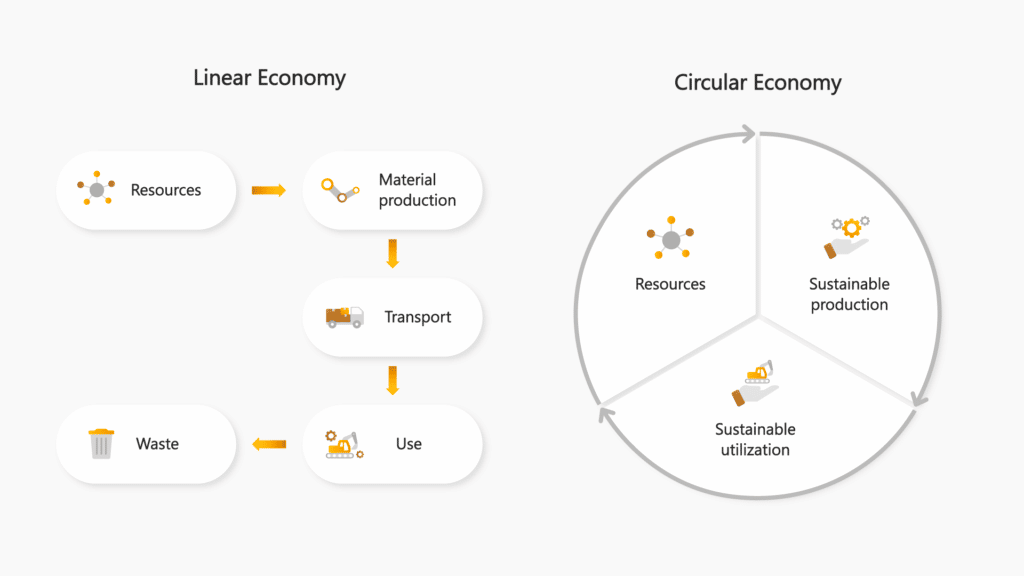

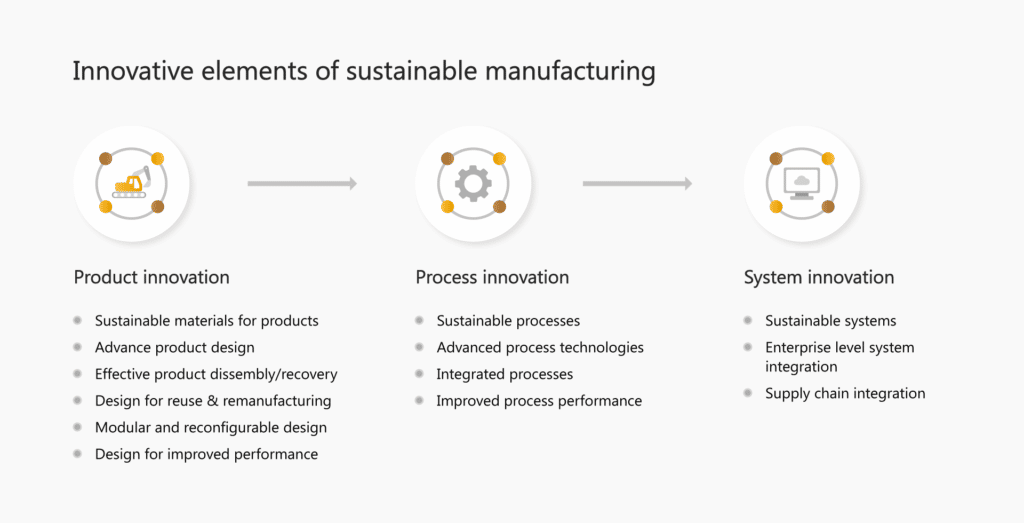

In the equipment industry, digitalization is driving operational improvements and cost reductions. A circular economy, on the other hand, seeks to maximize the resource usage of these industries. Fortunately, the two trends are complementary and can assist companies in creating a more sustainable future. By ‘designing out’ waste during the design phase, the circular economy can revolutionize how manufacturers market even before a piece of equipment is used.

However, the industry is full of complexity. Due to the sheer number of entities across multiple departments, data from legacy structured processes are proving to be increasingly unusable, resulting in a proliferation of “dark corners” where “waste crime” can flourish, making it difficult to assess and calculate how to extend the useful life of assets.

Shifting Gears: From Linear to Circular Economy

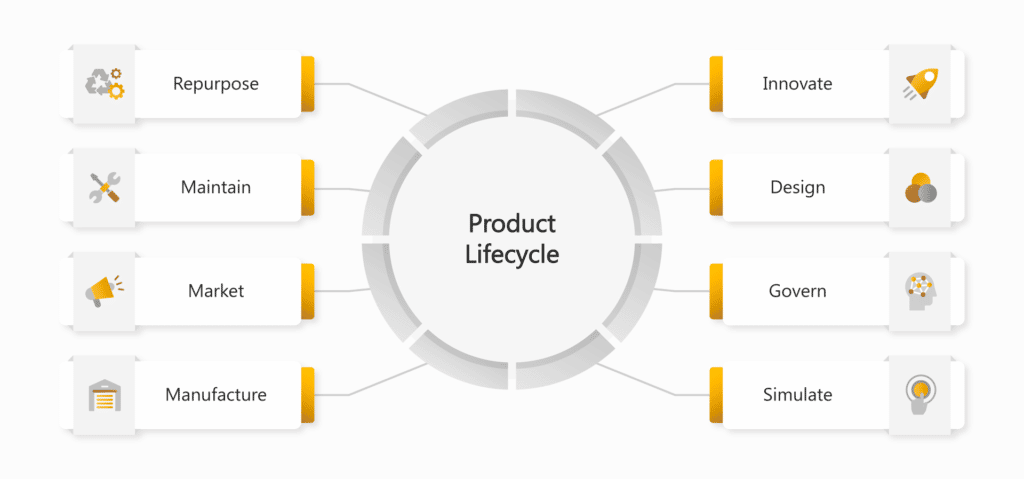

Adopting a circular strategy requires buy-in from the top down, as would be the case with any shift in business focus. It can’t be an afterthought added to an existing division; rather, it must be a fundamental part of the business. The key is to stop thinking about the circular economy to improve waste management and instead think about the whole lifecycle of the product, maximizing material use and reducing waste through refurbishment, remanufacturing recycling, and deconstruction. A circular economy strategy must include collaboration and visibility across the entire product lifecycle, from product lifecycle management to supply chain sourcing to manufacturing, sales, and marketing to aftermarket service, parts, and beyond.

By doing so, businesses will not just reduce waste but also:

- Retain and recapture the value inherent in the original equipment manufacturer’s existing products

- Reduce demand for new materials

- Reduce energy consumption through new manufacturing processes

- Adhere to regulatory obligations via environmental stewardship, making equipment enterprises more attractive to do business with.

Enabling a Data-Driven Circular Economy

To understand whether businesses are achieving the goals of a circular economy, leaders must have access to data that measures their company’s circular economy performance, starting with the earliest stage of their product lifecycle, in addition to the more commonplace metrics used to assess the business. With digital enablers such as IoT, Big Data, Machine Learning, and Artificial Intelligence transforming operations within the equipment sector, it’s hard to imagine any circular economy initiative that isn’t aided by applying these technologies. The incredible proliferation of the Internet of Things (IoT)-connected devices across manufacturing and logistics operations has provided decision-makers with unprecedented data and insights. Technology is undoubtedly essential for scaling up the circular economy, as it enables the generation and processing of data and information necessary for circular business models to meet the complex needs of circular supply chains.

It is critical to capture internal and external data, where businesses must transform their ERP software to implement change. It is also essential to assess the concrete outcomes of a company’s efforts to transition to a circular economy — to create a snapshot of its current circularity regarding material flows and business models. Companies can identify the right trade-offs and move their products closer to circularity if they have a birds-eye view of their operations and how they complement or diverge from public policies.

At Annata, we design solutions that give companies greater visibility into the responsible management of equipment and devices that enable them to track and comply with rapidly changing regulations.

Creating circular economy opportunities within the Equipment sector

Transitioning away from the conventional “take-make-dispose” model offers a significant opportunity to reduce environmental footprints, strengthen value chain relationships, and generate long-tail revenues. However, the move toward more sustainable operations, which focus on reusing resources and reducing waste, does require a re-examination of processes and products. Companies looking to the future have recognized and capitalized on this untapped opportunity by:

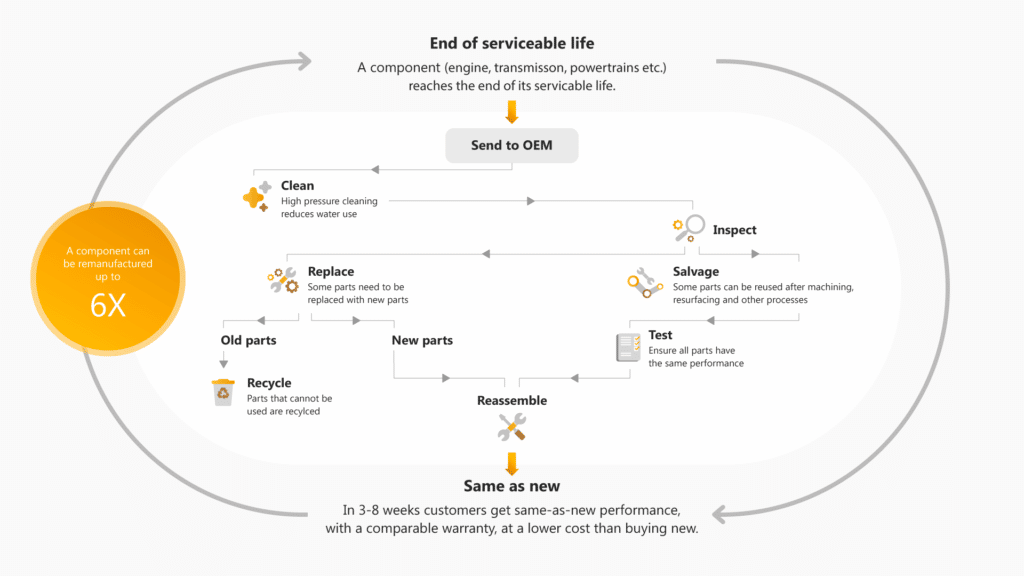

Promoting remanufacturing, refurbishment & repair

Given the economic importance of remanufacturing in industrialized nations, having a fully integrated solution to help better manage distribution, manufacturing, remanufacturing, service, and maintenance is critical. This must be accomplished with a focus on financial obligations, turnaround, a replacement unit, or contractual requirements. This can be crucial when working on products covered by a warranty or service agreement.

Creating a sustainable product lifecycle

To fully embrace the circular economy, manufacturers must use ERP software to manage entire product lifecycles—from maintaining, reconditioning, recycling, and supporting products over an extended period. These include managing the various methods of recognizing returning inventory, including Return Material Authorizations to keep track of reverse logistics channels as technicians service equipment and replace parts or components.

Sustainable Maintenance Practices

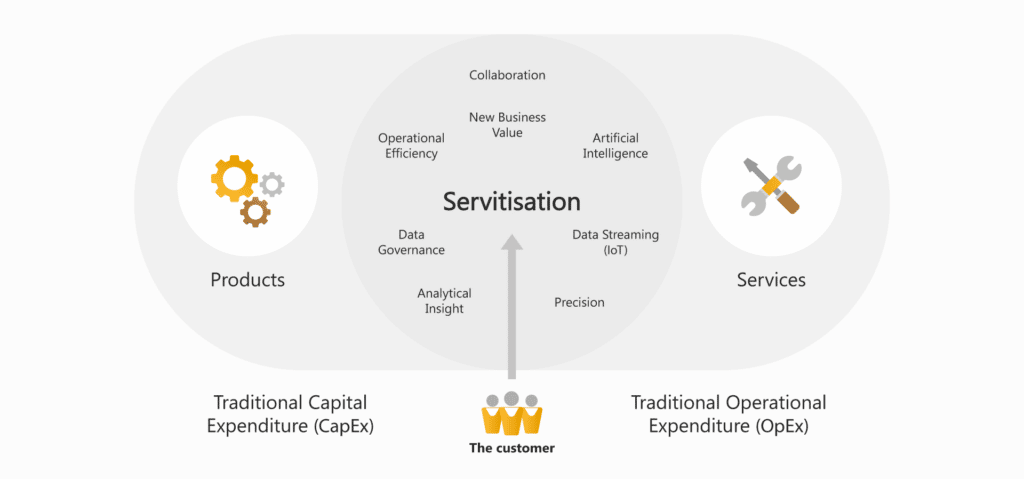

Connected devices and online platforms provide real-time data on the status of components, indicating when to maintain, replace, or repair components, resulting in more efficient resource use and longer product lifecycles. Predictive maintenance prevents unplanned service hours and keeps equipment performing at its peak, extending its lifecycle. With up-to-date maintenance, optimization, and cost analytics data, Annata 365 can help unblock bottlenecks impacting the transition to a circular economy and power new“as-a-service” models where capital equipment manufacturers can bundle maintenance and repair into the overall cost of a system.

Find out how you can unlock the value of machine data for your assets with Annata 365

Enabling Servitization for Added Service and Value

Often, the maintenance program is handled by a third party after the equipment has been sold, leaving the manufacturer out of the loop. When communication with the customer breaks down, the manufacturer loses all understanding of the equipment’s utilization, performance, and output. By incorporating servitization into their business models, equipment manufacturers can gain continuous access to this data, which improves their ability to analyze, understand, and predict life cycle and maintenance needs. Thus, closing the loop and participating in a circular economy.

Supporting the sustainability movement

Annata’s mission is to support our customers’ sustainability initiatives to analyze data availability and quality, enabling them to share and exchange this data in customer and partner ecosystems and across their value chains safely and transparently. Annata 365 provides this technological platform for enabling and complying with circular economy practices and new business models to help equipment businesses manage data and gain business insights. By processing inputs and raw materials more efficiently while reducing waste and protecting the environment, heavy equipment businesses contribute to the circular economy. The additional benefit of operational efficiency enhancements increases productivity and, ultimately, bottom-line results. It is an opportunity for corporations to play a more significant role in circularity as good corporate citizens to benefit current and future generations.

For more information about Annata, please visit our website at staging.annata.net. or click here to view our LinkedIn Page.