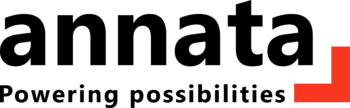

A collaborative OEM to Dealership integration framework

Original Equipment Manufacturers (OEMs) and dealers focus on attracting, serving, and retaining mutual customers. These two groups have historically collaborated in a mutually beneficial environment because OEMs typically get information from dealers on what equipment is moving and in demand. Conversely, dealerships require status updates on equipment and parts deliveries from OEMs. While the fundamental business model has not changed, industry pressures are urging key players to attain new levels of data flow to accommodate ever-changing customer preferences and behaviors.

Global markets in the equipment industry are expected to have the highest growth prospects across the board, and rising aftermarket opportunities will mean that the focus will shift from an operation-based to a customer-centric approach. This current shift results from customers expecting improved and seamless touchpoints and interactions influencing their purchasing decision. To gain deep customer insights and remain at the forefront of technology, OEMs must:

Getting closer to the customer means understanding how a machine fits into the customer’s way of business, where bottlenecks and inefficiencies exist in the customer’s processes, and where new developments are required to keep up with emerging trends. A secure and reliable integration framework will also act as a launching pad for improved marketing, selling, and servicing, ultimately leading to new business models and increased sales activity.

Data Integration matters

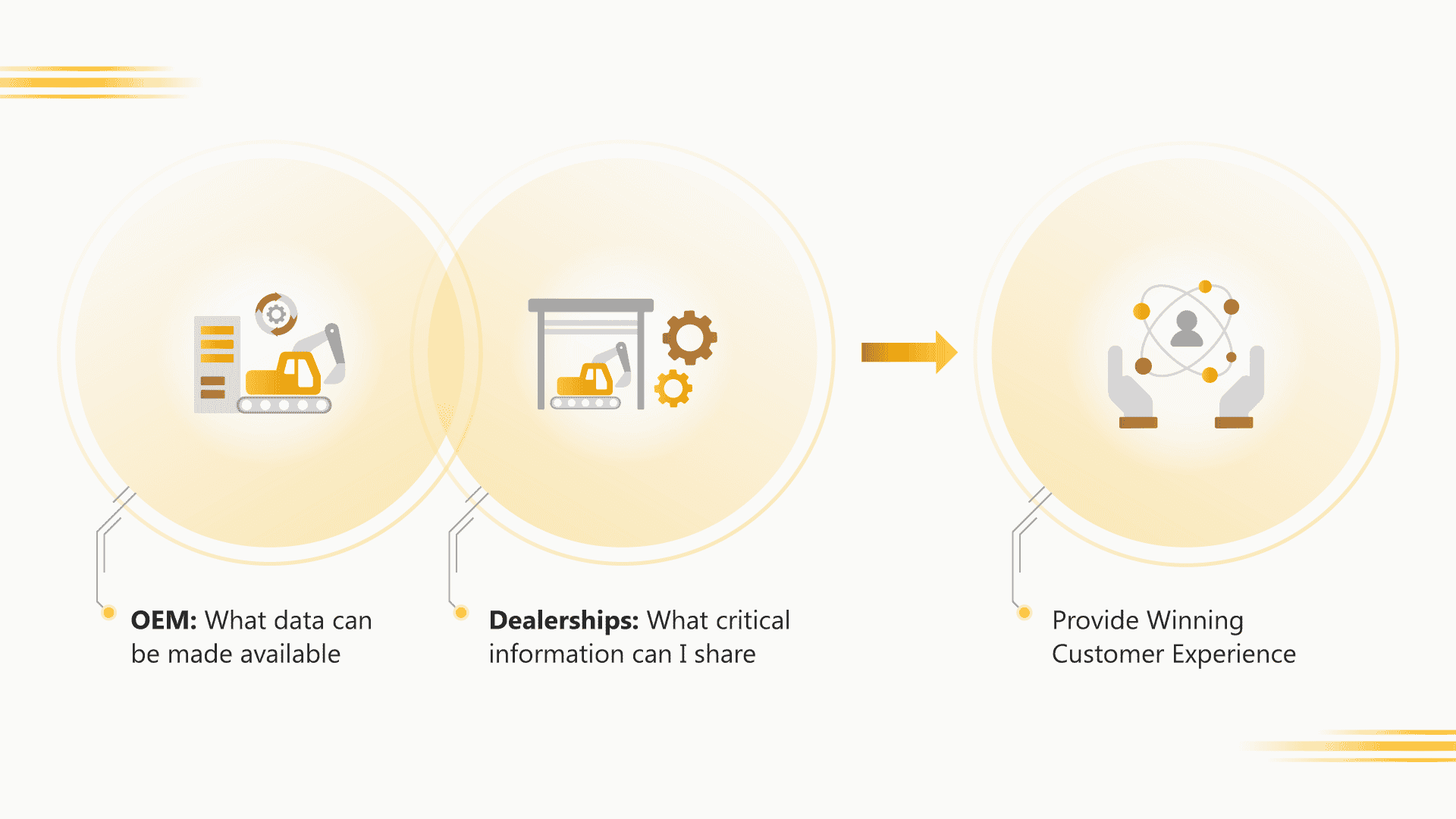

To effectively collaborate as eco-system partners, OEMs and dealerships must identify areas where integration is critical. These would typically be pricing files, online parts catalogs, parts ordering, warranty management, dealership locators, financial extracts, report uploads, telematics integration, and other functions within the business. Dealers could use IoT sensors, app, financing, and leasing data to engage customers, personalise products and services, improve, develop new ones, and upsell. OEMs and dealerships are arguably in a win-win situation in this regard, given the amount of data they can potentially tap to form a performance-based partnership. Unfortunately, only a few have committed to the bold vision of a unified communication and collaboration strategy.

Let’s take a deeper look at the challenges and how an integrated Data-Exchange application can drive desirable business outcomes.

- Challenge #1: Democratizing data along the network

The major challenge is resolving resistance to data sharing. To stay profitable, leading dealerships are taking a proactive approach when developing programs to increase sales and service and are focusing on implementing enhanced upselling advancements to create value in several areas. If these activities are proven effective, OEMs need to obtain a proven track record from dealers to fund these initiatives.

Solution: Purchasing information from dealership domains or data on lost sales can assist OEMs in making the financial commitment necessary to guide a customer journey personalized to their individual needs. Better integration can provide both parties with a comprehensive view of the customer experience, shifting their focus from “How are we doing?” to “How can we make customer experience our priority?”

- Challenge #2: Poor supply chain management

Low stock availability, poor channel alignment, and inconsistent pricing negatively impact customers’ retail experience, one result being intra-brand competition. Frequently, dealers that do not have the benefit of collaborating with their OEM to manage inventory often encounter some significant problems:

- Parts availability issues/ missing parts

- They struggle with pricing information and service levels for newly introduced product

- Aged inventory that is hard to sell

Solution: A shared 360-degree view can thoroughly understand inventory demand. OEMs can grant dealers access to inventory management systems that facilitate inventory planning, automatically analyze historical inventory data, and categorize channel pricing to differentiate inventory service levels. By working together, the OEMs and dealers can achieve optimal inventory levels through best-in-class planning.

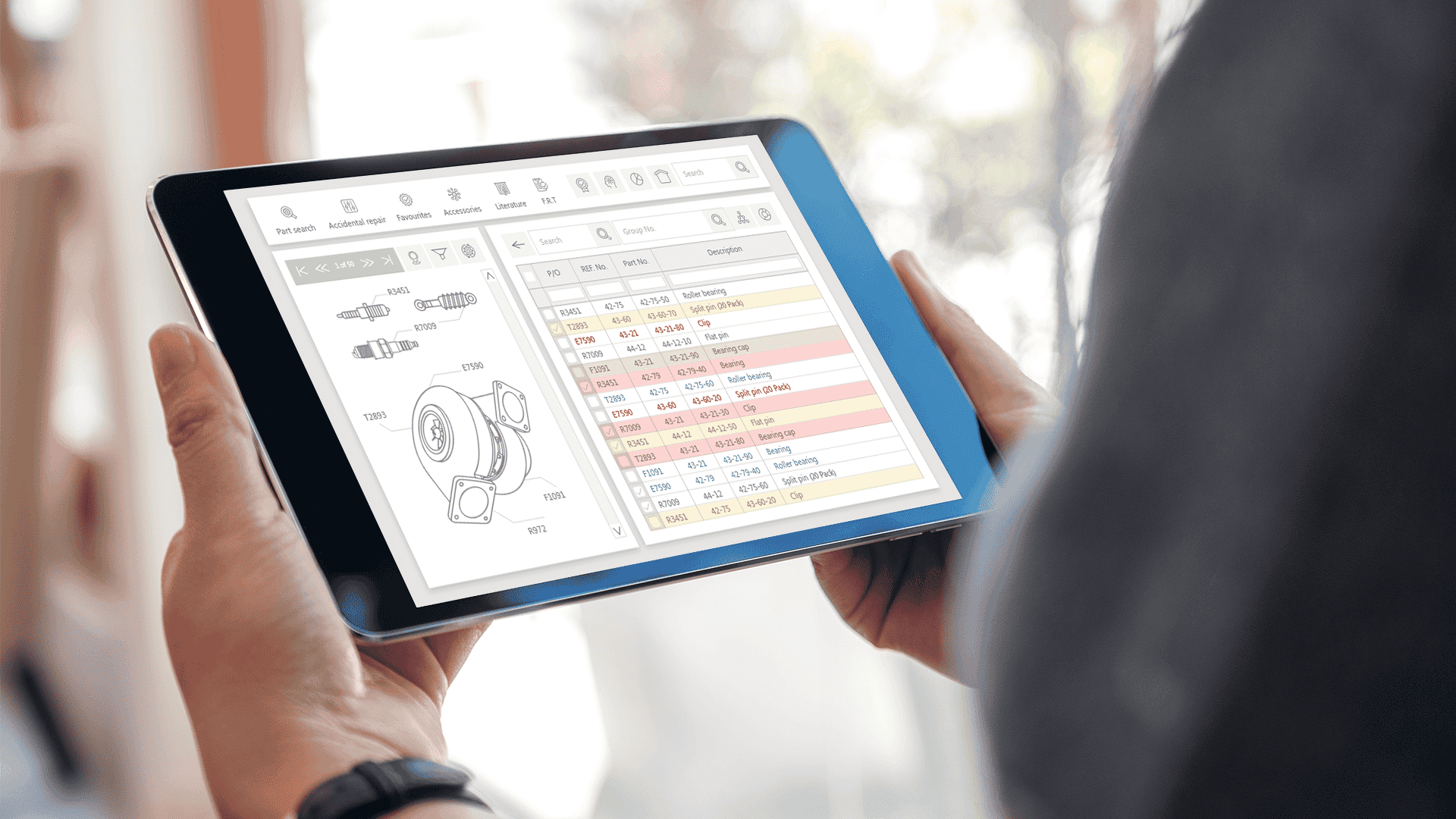

- Challenge #3: Unrealized opportunities with data and analytics

In the past, technology providers and OEMs have had a minimal understanding of internal dealer operations, particularly dealer DMS systems, which are the lifeblood of the dealer. As a result, the potential efficacy of data transmission has been limited, and the entire procedure has become cumbersome and, at times, extremely costly. This back-and-forth is mainly done with pen and paper or an in-house solution that would require their IT team to develop manual processes for extracting, validating, and standardizing OEM data. These disparate formats and file types are frequently error-prone, misread, or ignored, resulting in costly machine failures.

Solution: Using Analytics and tools such as Power BI to access available machine IoT data can provide insights into equipment health and performance. Custom triggers on key statistics can be configured to notify fleet managers who can collaborate with local dealerships, implementing remote diagnostics or predictive maintenance programs. Additionally, having valid and current data allows dealerships to right-size their fleet. For example, suppose one-third of their fleet is idle 80% of the time at a specific location. In that case, this information can be used to make an informed decision about cutting down or migrating those fleets to another site.

- Challenge #4: Error-prone warranty claims

For OEMs, it is necessary to verify and validate warranty claim data. Most OEMs find the process manually intensive as they still rely on paper forms in PDFs to gather information from their dealers. Cross-functional processes are limited, and many current systems cannot provide correct responses to all issues. For example, an incorrect code or data could lead to rejection of warranty claims.

Solution: Annata’s Warranty Management System for OEMs and dealers automates warranty claim verification and tracking, identifying areas for improvement and ensuring high yet profitable customer satisfaction. This solution provides OEMs with a single version of the truth, which can help them save money while improving product quality and supplier collaboration. In addition to lowering warranty costs, the solution enables OEMs and dealers to respond quickly to changing market dynamics and boost their brand image.

The Road ahead

The OEM-dealer relationship will certainly start focusing on experiences rather than being purely transactional, and it is no doubt that integration mastery will be a game-changer. Tighter integration allows OEMs and dealers to fine-tune operations, respond to market stimuli, and make more informed and strategic decisions. Implementing a comprehensive modern ERP platform can facilitate two-way communication quickly and effectively, with higher precision and decreased costs. This is the key to successfully overcoming this obstacle.

Annata 365’s open architecture enables data retrieval directly from the OEM to dealerships and vice versa and ensures a flexible and secure integration platform based on the latest Microsoft technology, along with our valuable know-how from hundreds of projects with equipment dealerships globally. We offer over 250 connectors to facilitate this transfer of information through a common data structure. Annata 365 is designed to keep pace with the needs of key players in the value chain that aim to be digitally connected to meet ever-changing customer demands.

Visit our LinkedIn page for more info, or contact us by clicking this link.