On December 16, 2023, we organized a webinar titled “From siloed systems to digital transformation: Powering success through unified integrations and enhanced processes.” The webinar aimed to tackle the challenges faced by businesses in the truck and bus industry, particularly the obstacles encountered when integrating existing systems with new technologies.

The webinar featured insightful discussions from industry experts, including Antonio Llorden, Digital Transformation Business Architect at Annata, who shared valuable insights into overcoming digital transformation challenges. Luiz Rochel, Business Development Manager & Senior Consultant at Annata, also provided expertise on how businesses can navigate the complexities of integrating new technologies into their existing systems to create one unified solution. Additionally, Dave Cope, Head of Global Black Belts at Annata, offered practical strategies for businesses to enhance their processes and achieve digital transformation success.

Moderated by Chantal Stravens, Global Customer Success Manager at Annata, the webinar provided a platform for engaging discussions and knowledge sharing among industry professionals. Participants gained valuable insights into the importance of unified integrations and enhanced processes in driving success in the truck and bus industry. The event highlighted the need for businesses to adapt to the digital age by embracing innovative solutions and streamlining their operations for improved efficiency and profitability.

Antonio Llorden’s data dive: Industry insights

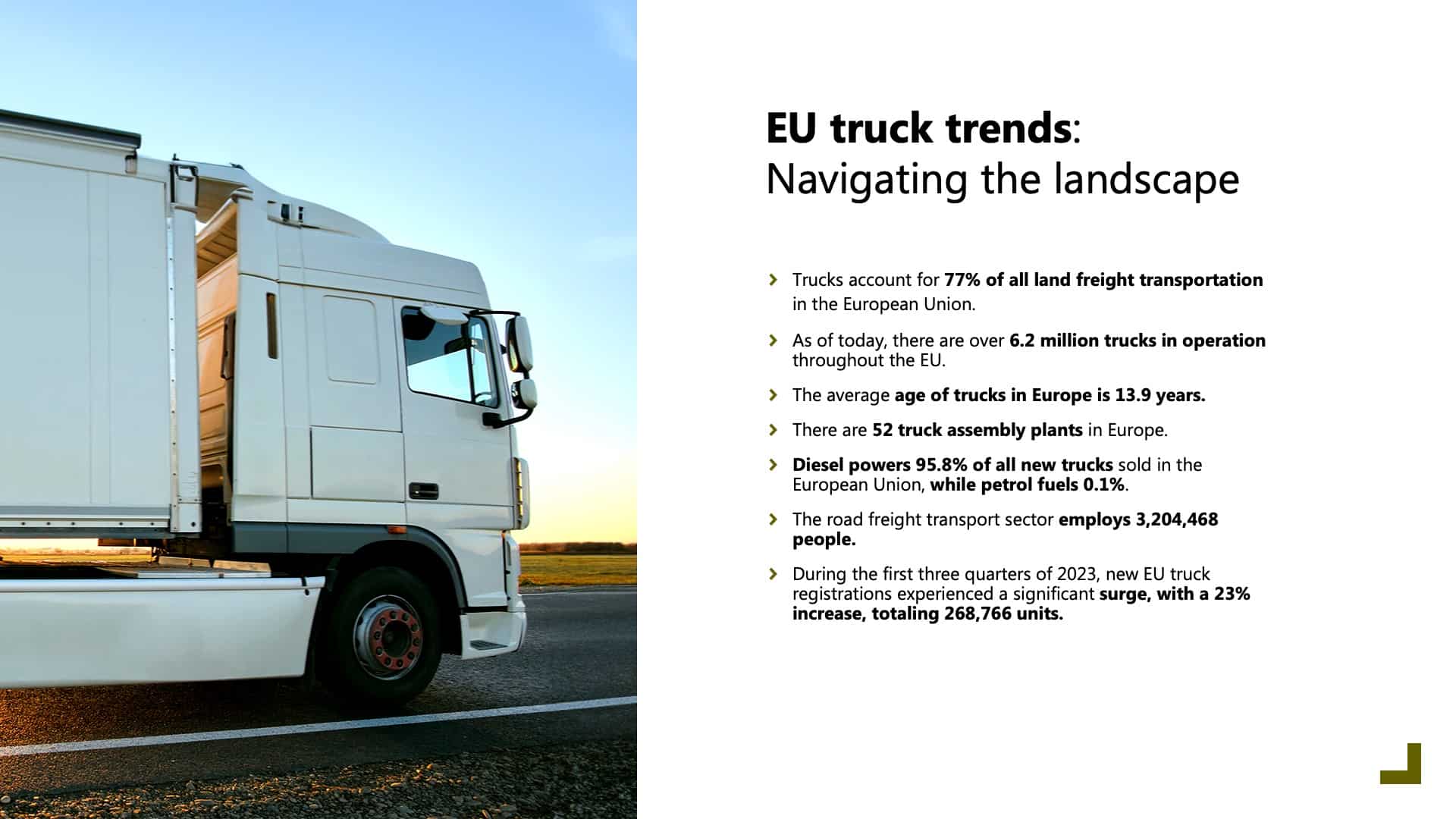

Antonio Llorden started the webinar by sharing specific figures for the automotive sector in the European Union. The sector provides 30 million jobs, contributes 7% to the EU’s GDP, and invests 60 million Euros annually in research and development. In the truck industry, there are over 6 million trucks in operation with an average age of almost 14 years. Diesel covers 96% of new truck sales, and trucks account for 77% of all land freight transportation. In the bus industry, there are almost 700,000 buses in operation, with diesel powering 70% of them. Buses cover 56% of public transport in cities. Sales in both industries showed significant increases in 2023.

Luiz Rochel’s roadmap: Trends reshaping the industry

Luiz Rochel then discussed industry trends, focusing on the flexibility of the supply chain and the technology that supports it. He highlighted the need to simplify the complex supply chain in the truck and bus industry to improve efficiency.

Customer-centric evolution: The omnichannel shift

Luiz highlighted that the sector is currently undergoing a significant transformation to operate more globally, with a strong emphasis on leveraging unified technology to address challenges posed by new OEMs and global issues. Customers are increasingly expecting a seamless interaction experience, including buying parts through e-commerce platforms, configuring trucks themselves, and even scheduling maintenance via dedicated apps. This shift towards an omnichannel approach requires brands to ensure unified and consistent information across all customer touchpoints.

New frontiers: Transforming ownership models

Another notable trend is the evolving ownership models in the industry. There’s a noticeable shift from traditional ownership to more flexible models such as pay-per-mile or subscription-based services. This change necessitates a corresponding adjustment in global distribution networks by brands to meet these new demands effectively.

Green revolution: Sustainability in focus

Sustainability has also become a central focus, with considerable investments required in alternative fuels, despite the fact that the majority of sales still consist of diesel trucks. As the industry transitions to electric trucks, there are significant changes in maintenance approaches due to fewer parts. This shift underscores the importance of unified operational efficiency and the need to simplify complex operations.

Global agility: Navigating industry disruptions

Furthermore, Luiz mentioned that brands need to react swiftly to global disruptions, such as supply chain issues, and implement solutions in a timely manner. Technologies like AI and chatbots are playing an increasingly vital role, prompting a creative reevaluation of system design and organization.

OEM strategies: Unified innovations for the future

OEMs are responding to these trends by investing in forecasting and AI to manage parts and truck needs globally. They are also transitioning towards selling complete solutions rather than just products, encompassing warranties, driver training, and predictive maintenance, all packaged into a convenient monthly fee. This shift aims to help fleet owners manage their fleets more efficiently with OEMs as strategic partners.

Smart solutions: Enhancing predictive maintenance

Luiz mentioned two key areas of focus. Firstly, the revenue generated from smart products’ predictive maintenance is crucial. Remote servicing is also gaining prominence, allowing mechanics to be guided by experts via remote systems to fix complex issues, such as those with electric trucks. This approach enables quick and efficient resolution of problems, ensuring minimal downtime for the vehicles.

Supply chain mastery: Harmonizing global networks

Secondly, there is a significant investment in streamlining the supply chain. Many OEMs have thousands of dealers across hundreds of countries, each with different ownership structures. The challenge lies in harmonizing and optimizing the entire supply chain to maximize efficiency and effectiveness.

Efficiency challenges: Overcoming process hurdles

Moving on to process efficiency, Luiz highlighted that while the market is growing, there are pressures on investments and profitability. Price pressures are reducing profits, leading to industry consolidation. However, there are opportunities to increase revenue and profitability by improving unified operational efficiency.

IT innovation: Rethinking core applications

One of the key areas where improvement can be made is in the IT platform. While it may not be easy to change the core applications, the potential for significant cost reduction and efficiency improvement is substantial. By automating workflows and harmonizing systems using AI and remote assistance, OEMs can streamline operations and reduce costs.

Unified solutions: Simplified integrations

Luiz also touched upon the complexity of the current scenario, where different parts of the business often operate in isolation, even within the same company. There are challenges with outdated systems and a large number of integrations, leading to inefficiencies and complexity. By moving towards a unified platform, OEMs can reduce the number of integrations and simplify their operations.

Annata’s promise: Pioneering industry transformation

Overall, improving operational efficiency is key to increasing profitability and meeting customer demands effectively. Annata’s platform, built on top of Microsoft technology, aims to address these challenges by providing a best-in-class supply chain solution tailored specifically for the truck and bus industry. By leveraging Microsoft’s cloud solutions and integrating trucks and buses’ specific requirements, Annata’s unified platform offers a comprehensive solution to optimize operations and drive profitability.

Dave Cope’s insights: Revolutionizing with Power Platform

Dave shared insightful information about how Annata utilizes the Microsoft Power Platform to empower the truck and bus industry with innovative solutions. By seamlessly integrating with Microsoft’s advanced tools for analytics, machine learning, and artificial intelligence, Annata enables customers to accelerate their time to value. The Power platform serves as a one-stop shop for building secure, scalable solutions that redefine business processes. These solutions range from conversational interfaces to mobile applications, offering exceptional user experiences.

Low-code revolution: Redefining development

Dave highlighted the flexibility of the Power Platform, catering to both seasoned developers and those without extensive coding experience. This versatility allows for the creation of unified portals for vendors, distributors, and even customers, enhancing interaction and data accessibility. By leveraging the Power platform, organizations can streamline complex processes, such as workflow automation and real-time analytics, leading to improved operational efficiency, unified processes, and customer engagement.

Additionally, Dave emphasized the cost-effectiveness of adopting low-code approaches, which can significantly reduce development time and costs. Projects that traditionally took years to complete can now be accomplished in a matter of months or even weeks. As organizations continue to adopt the Power platform alongside A365, the benefits extend to cost reduction, risk mitigation, and improved employee experience.

Empowering tomorrow’s workforce

Looking ahead, Dave invited listeners to an upcoming webinar series focusing on empowering frontline workers. This series will explore creating Power platform solutions and the impact of Microsoft Copilot and generative AI on workflow efficiency. Annata’s commitment to leveraging technology to drive innovation and efficiency in the trucks and buses industry is evident, positioning it as a leader in the field.

Stay tuned for future webinars

Thank you to our speakers, attendees, and everyone involved in making this webinar a success. Keep an eye out for future webinars and events where we will continue to explore the cutting-edge trends and technologies shaping the future of the trucks and buses industry. Visit Annata’s website for updates and announcements.